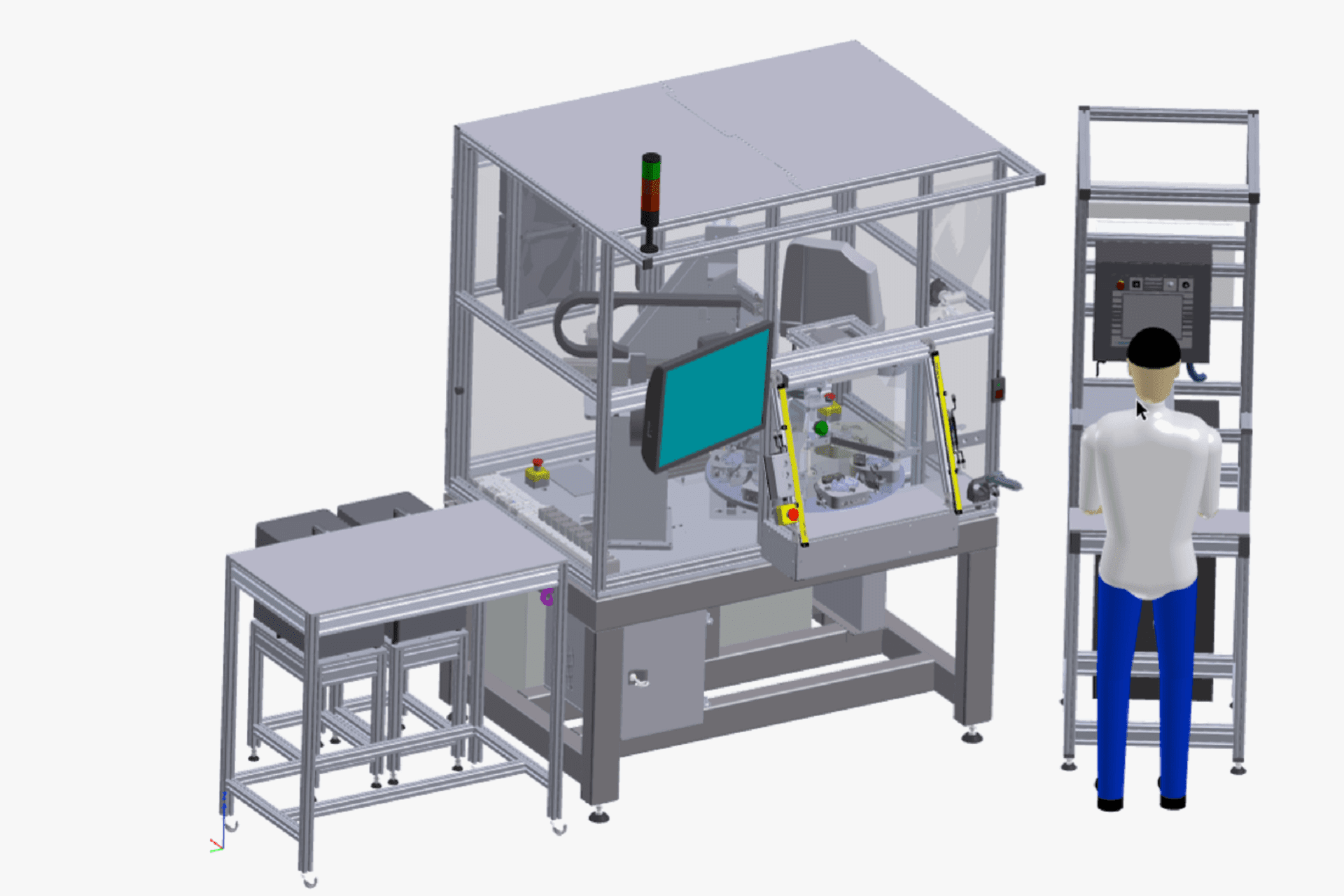

MES also measures production at the facility over time and visualises key figures. This helps establish a reliable overview of production, and allows the production manager or technical manager to track each and every product, so as to keep a check on the number of products in production, to identify any faults or disruptions, and to register traceability data.

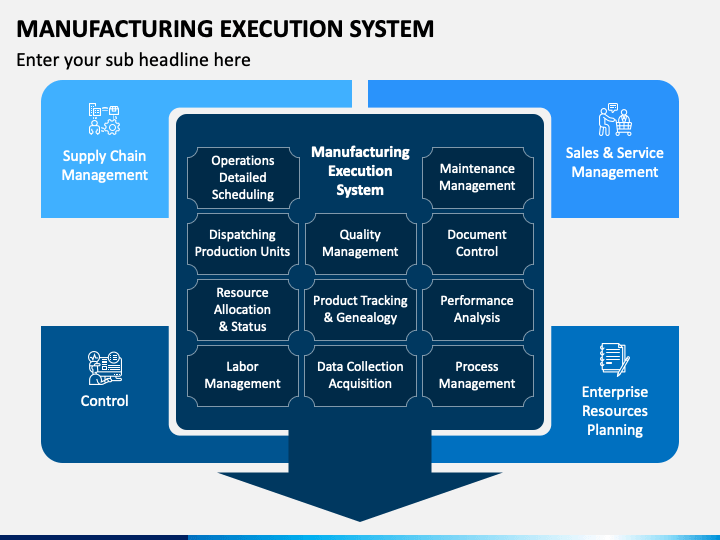

MES systems are primarily used for the management, monitoring and follow-up of production processes. Production management, production follow-up and quality follow-up

It is then possible to apply optimal control to production, ensuring that the refinement of the various products can be tracked and governed in every step of the process. From a purely technical perspective, the system creates a digital production flow that visualises the production process and links together the business system, machines and operators so they can communicate directly with each other. Empir Industry’s Manufacturing Execution System contributes to improved efficiency, quality and traceability. The market for digital solutions in industry continues to expand, especially in the light of the tough competition that distinguishes the sector, and the ever-increasing demands for efficiency and profitability. Given the current market requirements and the state of competition today, Lean manufacturing and increased productivity are key concepts in all kinds of manufacturing.

Our Manufacturing Execution System (MES) products help you improve the efficiency and quality assurance of your production.

0 kommentar(er)

0 kommentar(er)